Guest Post by Walt Barrett part 1.

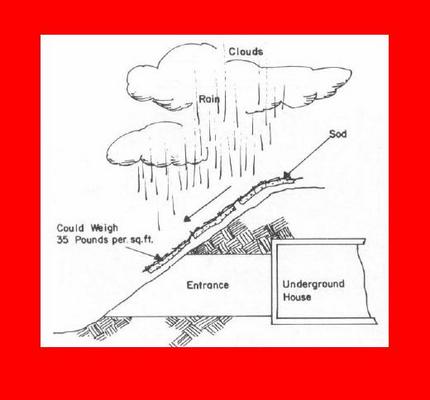

Here in New England it gets pretty cold in the winter, and the temperature hovers around the freezing mark. We have already built a 128 square foot micro home to use as a test bed for our energy saving products, and now we are giving serious thought to building an underground micro home test bed so that we can better deal with the cold and windy winters. Our test model, due to space restrictions, will most likely be 100 square feet with only a solar passive heating light wall, but for a full size home design I am thinking about using four shipping containers arranged in a rectangle with a large tempered glass ceiling light well in the center.

Each container would have a door, or doors opening into a central light well patio area with a year round garden. We could cover the exterior walls with waterproof foundation sealer, and then glue on foam to the exterior the same way we cover our concrete foundations now as per our local building codes. The entire project could be set on a suitable concrete slab. The location can be either on a flat lot, or dug into the side of a hill where an additional solar wall could be added. An important note is that you must have at least two escape routes to the outside in case of fire. One can be in a corner of the light well.

Many people already realize that by going mostly underground the first 55°F in the home temperature is a 100% free ride. When you add to that the heat gain from people, refrigerators, cooking, lighting, washers and dryers etc. you pick up a considerable heat gain. However there is also going to be heat lost through ventilation because no one wants to live in a swamp filled with stale air either. Light wells and solar walls can be an asset in the day time for solar heat gain, but must be insulated at night. There are several ways to accomplish this. Some methods are insulated curtains, sliding walls, Zome walls, or sliding covers. Solar light walls and light wells must also be shaded in the warm weather or you will find yourself living in a large solar oven.

If you design your underground container home properly it will cost far less money than a conventional above ground home, and the heating and cooling will be a virtual free ride if you engineer the home properly. This is not a new idea by the way. I had several neighbors that lived in poured foundations during the depression of the nineteen thirties, and some others joined them right after world war two when we had a bad slump in the economy. This was a common practice here in New England during the thirties and forties. You do not need a large central heating system, or air conditioning system either. I also know several people that own large above the ground homes that they can no longer afford to heat. They have made apartments in their cellars to live in in the winter. They drained the above ground plumbing for the winter. They are saving a fortune in heating bills, and they move back upstairs in the warm weather.

People have been living under ground for thousands of years because in most cases they had no choice. With the ever rising prices of fuel we now have to take a long hard look back into the past, because the past may be our future again. I advise you to give it some thought, and play with some designs of your own to make the idea more palatable. Personally, I’m going to work on it, and my design will be totally off the power grid.

A little imagination goes a long way.

© 2010 Walt Barrett President A to Z Global Marketing Inc.

Contact Walt Barrett for permission to reprint.

Have you done any research into the structural integrity of the containers when buried?

I have thought about using steel or concrete culvert or composite prefab tanks/shelters; they may be more costly, but are engineered specifically to be buried.

there is a large house here in Texas that is made from burying shipping containers. It is by no means a small house.

Remember.

a standard shipping container is made to take the weight of dozens of loaded shipping container stacked on top. So a full ‘tainer has on order of 40,000 pounds of weight (A rough estimate, some are more, many less (those I fill, 20’ long, have 37440# in them, plus the weight of the ‘tainer) and may have 20 or more like containers stacked upon it in the hold of the ship. In storms.

The last thing you need worry about is if some dirt on top of one is a bit much.

Is the weight of the dirt only on the corners and edges of the roof of the container, like it would be when another container is stacked on top of it? Or is it spread over the entire roof of the container? How about the pressure on the sides of the container? The container doesn’t have to contend with pressure on its sides while sitting in a shipping hold, yet concrete basement walls frequently buckle and crack or bow inward in peoples’ basements. I would think there are too many differences to be able to say that just because it can handle the weight of another container during shipping, it can handle all of the various forces it will be subjected to buried underground. How about when that earth is completely rain-soaked? What about corrosion caused by constant contact with damp earth? Certainly these aren’t things that a shipping container was intended to have to deal with.

It’s an interesting concept. But when concept meets the realities of mother nature, I’m not so sure that what looks good on paper looks as good in the ground.

The roof is as thick as the sides, and the metal is there to give strength and support to the corners. A container on ship doesn’t have the weight of one more atop it. If it is at the bottom of the hold, with only 9 more on top of it you are looking at 405000 pounds on top of that one container. The support is the corner cage, but the floor, roof, sides, and the doors are adding to the integrity of that structure. There are “containers” that have no sides, and are basically a cage for odd shapes, or tanks etc. The cages are far thicker on those to compensate for the lack of sides.

You would need to be burying it in lead shot to really worry about the loading of the metal. it is rather thick. The stuff is not as thick as casement steel (used to hold back levees and ground from basement levels during construction of sky scrapers), but is plenty thick. You’re not planning on setting Mt Washington atop it after all.

Corrosion would be prevented with a spry treatment, but remember, these things sit out in the open on a ship sailing on salt water. Talk about corrosive environs! You’d want the best shape roofs for certain though.some get dinged and often the reason a container is sold off is it leaks. Then again, there are sellers who buy them, and repair them to your specs.

We have an ex-refer unit to be used as hot storage. It is a 40′ insulated container with a second set of doors welded to the opposite end (the new door operate far better than the originals that are sprung slightly) and we will be putting in some electric heaters as some of our products and ingredients freeze near room temp, and others are high viscosity.

Well, my reply to you there is to direct you to the link provided below by MissLou… it seems my assertion that there would be some serious problems (although it came about because of problems I only perceived, nothing based on experiences, observations, or things I knew to be fact) is shared by others with first-hand experience and scientific calculations to back it up.

Walk on top of a conex and then see how you feel dumping a ton of earth on top of it with you inside…they’re built to hold weight on the corners and that’s it.

back in the caveman days there wasn’t foam. Is it necessary to go underground when we have foam panels? Before this green movement,20yrs ago, I made foam window panels for winter months,I had the fiberglass insulation in the walls,however,this year I insulated the walls with foam panels.Also, the cellar ceiling. It is so easy to keep warmer this year. I am such a fan of foam insulation, no matter what form it comes in.

I like the idea of the energy savings, but the loss of light could have a negative health effect (S.A.D?) Also you should consider a safety exit in case of landslides, avalanches, earthquakes and the like.

You could look into light piping, or keep one wall unburied/exposed like a more traditional earthbermed home.

This article perpetuates a myth that underground temperatures are “55 degrees.” That depends upon several factors–but is generally within a degree of the annual average air temperature in the location involved. In the far Northern parts of the continental U.S., the stable ground temperature averages only in the 40s. In the South, it may be into the 60s or even low 70s.

Thanks everyone for commenting. I believe that part two of this article will cover most of the comments so far. You can have all the light you want with the new low wattage lighting systems that run on solar power, earth batteries and bio fuel cells. It is up to the individual to consider all the comments both negative and positive and then decide if living underground, or partially under ground is for you. I do not expect everyone to agree with my writings. I am simply offering some alternative life style/housing suggestions. Someone has to do it, for better or for worse. It gets people thinking about the problem and that is my goal.

I submitted part two yesterday. It should clear up most of the questions. Sorry if I perpetuated any myths. I expect that most people know their local ground temperatures better than I do.

Mostly, I want to stimulate people to think about the housing alternatives of the future. I expect to learn from your comments back to me as well. I am extremely concerned about the number of homeless people in our society, and I will continue to write about the entire subject, and to build more experimental homes and test more energy systems. It has to be done.

Thanks,

Walt

Thank you for the article, and I agree that building underground is very energy-efficient. I myself would love a hobbit hole to live in (more cash than I have right now though).

However, to everyone who reads or writes for this blog, please believe me when I tell you that people will die if you drop a dump truck of earth onto the top of a shipping container. Walk on top of one to see how thin that steel is up there. It holds weight on the corners–that’s it. Look to corrugated steel pipe or pre-cast concrete pipe: anything round gets a huge benefit of the natural strength of the arch.

Where’s Part 2? How do I follow you?

If using shipping containers you would NOT need a concrete footer either; just a nice level cleaned stone layer with drainage and sump pip for water removal! Also leaving one side exposed would give all the light you need and possibly drainage without a pump depending on site elavation!

Very interesting indeed!

Randy

I have an above-ground shipping container made into a bedroom and it gives everyone the creeps. They all crowd into the TINY TINY cabin. I guess we are all too used to sunshine here in California. This would be a wonderful idea for folks who feel “cozy” in such areas. I know in very hot places in California people build partly underground with filtered light and I myself have a basement with lovely ambient temperatures in the summer but it is only 1/2 underground. My next door neighbors are from Iceland and they are constantly sitting out in their undershirts in February “summertime weather”, so I think this design will not be for many people. It IS an interesting design.

http://www.williamlishman.com/underground.htm

Bill is THE MAN when it comes to underground dwellings. He is always in demand when it comes to his expertise and as such one will have to pay for his time. Regardless, living underground is something that can be accomplished…with some cost however.

No no no – don’t do it! Shipping containers are built to be stacked on their corner castings – the walls and roof give rigidity and some strength, but *n*o*t* enough to bury.

This posting should pretty well explain it:

http://renaissanceronin.wordpress.com/2009/11/07/okay-go-ahead-dig-your-own-grave/

and it’s not being sarcastic or ironic (much). Unless you are going to do a sh!tload of structural modifications, and some severly expensive groundwater management preparation, you’re just going to end up with a flooded, rusting mausoleum that’s collapsed in on itself.

Yes, you need to check your areas “deep soil” temp it is indeed the average of the year round temp…a good idea for example if there are caves nearby…real ones with bats etc. the Temperature inside the cave is your Annualized temp.

Northern Indiana about 42 degrees, Carlsbad in NM about 56 degrees, by comparison people in far north of Alaska have under ground freezers that are completely energy free…can you say Permafrost!

For more infor on this I wrote up a little at my blog… http://kmswoodworks.wordpress.com/2010/01/13/small-living-vs-sustainable-living/

Earthships, Passive Annual Heat Storage (PAHS)

and annualized Geothermal Storage (AGS)

Regarding the air replenishment, PassivHaus dwellings (& many others) use forced air systems with heat exchangers to extract the heat from the air being extracted and warm the incoming fresh air. PassivHaus dwellings are built very highly insultaed and draight-proofed.

“Earthships” (http://earthship.com/ & similar designes: http://www.groundhouse.com/) are built into south-facing hills, or bermed around the north side on flat ground, to provide large heat store with plenty of light. This is a trusted architectural solution without goign entirely underground.

My family and I just survied the Joplin, MO tornado on May 22. We were home when it hit and it totally destroyed our home. We somehow survived with only cuts and bruises even though the entire structure exploded around us and was leveled to the subfloor. This home would be of great interest to us. We survived one EF5 and never want to chance it again. If you get any serious plans about this contact us please.

Thank you,

David Wilson

I love this idea, I’ve been thinking about it myself. FYI everybody, surf the web, container homes can look fantastic and stylish, it’s all in the design. Nobody but you is trying to bury one though, so kudos to you!

Also, to get the most from the solar heat, and to preserve the containers from corrosion, you should consider using the principals of Passive Annual Heat Storage. You want cover the dwelling in dry dirt, then a waterproof, insulated layer 20 or 30 feet from the foundation, then more dirt. The dry dirt under the ‘umberlla’ warms up in summer, cools off in winter, a HUGE heat sink. Ventalation is with two 200 foot 4 to 6 inch tubes, one high, one floor level, that curve through the dry dirt to the outside, convection does the rest.

Google Rocky Mountain Institute PAHS home, they did a lot of research.

I’m looking forward to seeing how your project works out. Good luck!

P.S. I think you might have to bracer the ceiling. The dirt, although lighter because it’s dry, is still very heavy. Definitely a question for an engineer. I guess I’ll go over to our university and buttonhole an engineering student in a pub!

Oh yea! Make sure your structure is above the water table! A south facing hill would be ideal. If you pay careful attention to getting groundwater to drain properly over your ‘umbrella’ to weeping tile beds at the edge that draw the water away, I think this structure could last 500 years without any maintenance (ok, replace the windows every 30-40 years). It would require no heating or cooling. Hurricane proof too. Truly the house of the future.

Three feet of earth is a rule of thumb for coverage of a standard steel shipping container without additional support. Any more than that and the sides start buckling inward eventually. There are variables such as soil types and compaction density. I can live with three feet properly done.

Or you could just a regular house with ICFs.

I think the bigesst issue will be about water trough earth, saw a project of a cellar where they build a “box” about 30cm all around the construction that helps to prevent it, just an opinion sorry for my english.