Ian Anderson one of my readers contacted me about his tiny house project. Ian wanted to wait until a time when there would be more frequent updates before he had me put it up on the blog. Ian has been so close to this project for so long that it is hard for him to tell what people want to see.

I think that you will agree with me that you will want to follow along as he gets busy this spring so I think now is a good time to share Ian’s build with you. I’ll let Ian tell you more about his project.

Several years ago, a friend of mine showed me the Tumbleweed House site. I loved the idea of living a more sustainable, compact and cheap lifestyle by living in a small house. I immediately started sketching out floor plans for the way I would build a house. At first these plans were just a creative escape for me while I was trying to focus on my engineering classes. I returned to it again and again throughout the next two years of school. It seemed like a great way to apply my love of design and building to something practical that would benefit me and others for a long time.

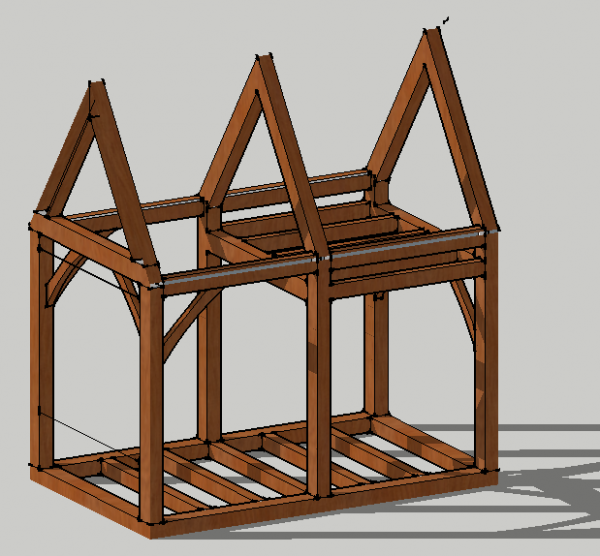

Immediately after college, I attended a two-week timber framing workshop at Fox Maple School of Traditional Building in Brownfield, Maine. After this workshop, I knew that I actually wanted to build this little house, and I wanted it to be timber framed. My idea for the project became more cohesive. It would be built out of materials salvaged from existing buildings, or at least manufactured locally on a small scale. Influenced by the ideas of the Arts and Crafts Movement during the early 20th century, I want as much of the house and the things in it to be built by myself or by people who I have actually met and who put care and thought into their work. Like many of the other small houses I have seen, this one will also be somewhat mobile since I don’t have a long term location for it.

Anyway, check out the blog if you want to learn more about the project! I am hoping to move into it this spring so there should be a flurry of activity over the next few months. Visit the Little House Blog.

Wow,beautiful workmanship. It must be very heavy! How will you move it? It certainly should be able to support a heavy snow load, looks indestructable.

Thanks for the compliments! It is heavy, the frame should be just under 2000lbs with dry wood. Now that I have decided to use oak for my floor it will definitely be heavier. I have a trailer for it that is the perfect size and should handle the wight for it’s first move (just across town), but I will probably build a trailer specially for this house in the future. I don’t plan on moving it too much, but i do want to have the option if I want to change location. With the roof in place, the building will be too tall to trailer legally, so I am building the roof to be removable. It will be built as two bolt on panels that will have pine paneling on the inside, a light 2×4 insulated frame and metal roofing (hopefully standing seam copper) on the outside. When I want to move, I can unbolt the panels, lift off the 3 rafter sets and lay everything flat on top of the building. For the actual lifting of the roof pieces, it is amazing what can be done with an old block and tackle and an overhead tree branch! That’s the plan- it is definitely likely that things may change when I actually get to that step though.

Any interest in posting plans for sale? This is actually something I would be interested in doing or building down the road, and would be interested in finding somebody to fabricate.

Nicholas, As I am nearing the completion of this frame, I

am definitely interested in building another. I have really enjoyed

the process and would love to build another, correcting mistakes I

made on my own frame. I will post more info on my blog when I am

ready to build another. If you are serious about building or having

one built, feel free to email me from my blog

(www.littletimberhouse.blogspot.com).

Very cool! I never would have thought to apply the timberframe concept to a tiny house! Gotta love the joinery and craftsmanship that goes into any timberframe project!

Love it! Looks great so far. But I want to know more about the building you are making it in. Very cool looking. The wood panelling, high beamed ceilings and the huge staircase are amazing. What a shop.

Bill,

My shop/house is an old fire house that I am lucky enough to live in. It was built in 1900 when people still cared about the aesthetics along with the structure. It has a few old iron beams in the ceiling, beefy wooden joists and full 2″ thick floorboards to give the main floor a full clear span- perfect for a timber frame shop. The front of the house has two 10’x 12’tall doors that used to be used by the horse drawn fire engines. Now they make for a convenient way to move a small house out. In the summer it is nice to work with the doors open for fresh air, sunlight and passerbys. I live in a part of the city where things like this are uncommon to say the least(not that they are terribly common elsewhere) so I have lots of interested visitors stopping by to check it out. One day a neighbor came over while I was splitting wood and asked if he could give it a try. He had never seen anyone split wood before! It is little memories like this that will stay with my little house forever.

Cool, what part of Mass are you in? I see your shirts says Worcester…

Worcester

Wow, sweet. From the pics it looks like Western MA. I just moved from Worcester to Holden…

I’m in there with BillS…looks like a cool old building that is acting as timber frame workshop…the timber frame is cool too.

You must go to his blog and check out his drawer/shelving collapsing/expanding spiral staircase idea. It is pure genius. I love staircases and have been trying to conceive of a space efficient way of accessing the lofts in so many of the small house designs. I imagined using an alternating tread approach or a staggered book case approach, but this is truly the best idea of I have seen yet. He writes that he has yet to work out the engineering of the system, but the idea alone is pure genius. The staircase alone deserves it’s own article on the Tiny House Blog.

Beautiful work….I just found this site today and I love it! Ian I like your modular roof design idea…hope to see pics. This site has got me thinking….

Hi Ian,

Awesome project! I was just wondering if, in your opinion, it would be possible to use smaller dimension timbers for the frame in order to bring the weight down? I guess that might be a question more suited for an engineer, but I figured that with a smaller structure, one might be able to use a leaner frame. Maybe there are other considerations (I don’t know much about timber framing).

Thanks for the inspiration!

Hi Aubrey, Sorry for the delay, I didn’t notice that I had

more comments to respond to. The short answer to this question is

yes. I actually am an engineer, but for this project I didn’t

bother to calculate the size of the beams. They could have been

smaller for sure, but this had the right look once the walls were

built into the frame. If I do it again, i would probably decrease

the size of the timbers and apply the walls to the outside of the

frame rather than filling them in between the timbers. Live and

learn!

Outstanding workmanship Ian, very well done! I am really looking forward to seeing the stairs work, and to find out how stable they are, that looks like a great solution to gaining access to your loft, and I love the creativity in your tiny house.

Hey Ian,

Nice meeting you last night. The house looks amazing. Can’t wait to see it on Sunday.