by Laird Herbert

Leaf House has a new home in the Yukon, Whitehorse, Canada, and is back in the thick of tiny house construction. Plans for version.2 are complete and for sale on the website www.tinyhousing.ca, and Leaf House will be building one more custom tiny house this winter.

The company is testing a variety of innovative materials and technologies suitable for tiny house construction in cold climates. Leaf House is using this upcoming tiny house as a case study, incorporating extremely energy efficient windows, an innovative compact Heat Recovery Ventilator (HRV) for small spaces, a lightweight concrete finish for countertops, metal mesh rainscreen, aerogel insulating material, and lightweight panels and interior finishes.

The most exciting technology showcased in the tiny house, which is the subject of this post, is the vacuum insulated panel (VIP). VIPs are an insulating product that is not yet available in commercial construction but have incredible potential for tiny houses and the recreational vehicle industry. VIPs are thin (1/2” to 1”) yet have an R value of R30 per ½”. The extremely low pressure in the panels prevents heat transfer, and overlapping the panels means that a wall of R60 can be achieved with only 1” thick of material. The panels are filled with silica and are also lightweight. The space and weight savings mean that tiny house construction might just be the perfect application for VIPs.

An R30 VIP panel

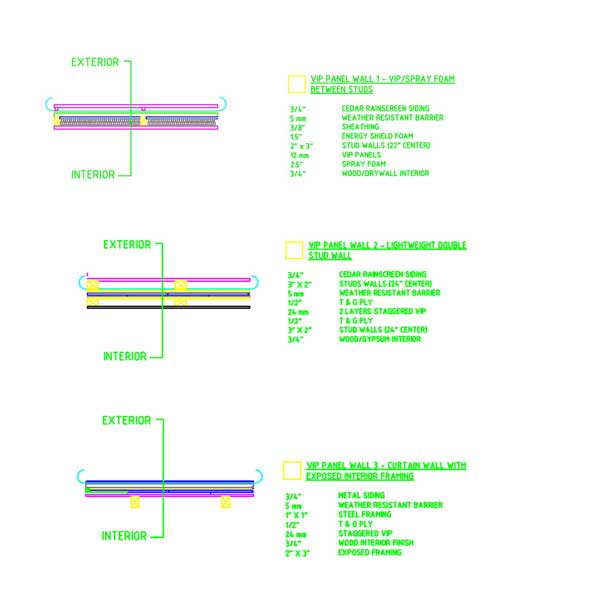

With VIPs tiny house builders can use 2X3s, 2x2s or metal tubing for framing, reducing the overall wall size significantly, yet achieving R60 efficiency with little weight. Leaf House will be building three different kinds of walls to test different wall designs. The first is studs on 24” O.C. with the VIPs and a layer of spray foam between the studs which also acts as a vapour barrier. The second is a double stud wall with a double layer of VIPs for R60 on the north side, and the third is a curtain wall that will also be R60 and hang over the structural framing.

Wall Layouts

The biggest challenge posed by VIPs is that they cannot be cut, bent or modified in any way. This means that the tiny house must be designed to the dimensions of the panels, including the rough openings and around the wheel wells of the trailer. Any punctures to the panels will break the seal and they will no longer function to such a high efficiency, which means construction can be a little nerve wracking when using a nail gun. Leaf House is countering this limitation by wrapping the entire structure in R-8 foam and then spray foaming any gaps in the VIP panels, creating a vapour barrier in the process.

Conceptual rendering of Case Study Tiny Home

VIPs just may be the ultimate material for tiny house construction or RV manufacturers. They allow an R60 wall to be built in an incredibly compact footprint, an option which has not really being available to tiny house builders to date. In the Yukon being able to build such an energy efficient tiny house wall is a huge advancement for cold climate construction and the technology will have important ramifications on construction in the north. Please keep posted to the website www.tinyhousing.ca for updated pictures of the tiny house and information on VIPs, as well as the other technologies showcased in the tiny house. Expect to see the completed home to be posted for sale by May 2013. Manufacturers can source the panels from Panasonic Canada.

I wonder about the viability of VIP from a sociological POV. Most folks won’t heed the warnings on a cigarette pack, let alone a sticker on the wall concerning penetration, use of surface mounts only and prohibitions against modifications to the structure of any sort. While an initial purchaser may be willing to heed such limitations, the third or fourth generation owner may not be as committed.

Probably the greatest limitation of this product.

Wow Laird! I love Leaf House (original ) and this new revision looks fabulous! Thanks for striving.

As far as I know in Europe these panels have been around for more than ten years…

Interesting concept. I would like price information on these panels. These panels are used in industrial applications.

I do not think the average budget minded person will be building a small or tiny house with VIP anytime soon.

Great to hear these are being field tested on your tiny house, what is the cost per square foot? I have heard of these being used in the aviation industry and in some nautical applications but assumed they were cost prohibitive, maybe they aren’t?

What is the manufacturer of your min HRV, I know Panasonic has a smallish ERV?

R20 Windows!? .05 U-factor, thats incredible. What company is making these and are they rated by National Fenestration Rating Council?

Sorry for all the questions but you have posted a lot of new and great things, but I am slightly skeptical of an R-20 window.

Thanks again for sharing.

The cost per square foot isn’t quite set yet – I think we will need a year or two more before that’s established, but my hope is that it will be slightly more than spray foaming here in the north – so that the costs are almost comparable. They are expensive, but they are a fairly new (at least fairly new success with the seals) so it’s to be expected.

There are a couple HRV’s the Lunos E2 fan, and the Venmar Eko 1.5. The Venmar is more proven in cold climates, we’ll see how the Lunos does. the Panasonic doesn’t work in cold temperatures, simply exhausts. I can’t stress enough how important it is to put one of these units in tiny houses – especially if it’s airtight. I would rather forgo a composting toilet for a bucket toilet or the basic separett and put a HRV in instead if it’s a matter of budget.

The windows are suspended film R20 claimed center of glass. Ecoglass.ca is the source for those. They are light but also quite expensive. Cheers, Laird

ps. these costs are something we have to included in cold climate construction

Just like all ‘innovative’ widgets, the push back can be useful!! Cost by Damned, if the project is worth the experiment of the original concept! With technology of today and tomorrow all things made by man will be done!! Yes, there is ‘indoor’ pollution, so what! Innovate a ventilation system or off the shelf, but don’t stop on your or others with innovative original ideas, because others will say, ‘I knew it would fail’ or Gee, I wish I had done that! It’s an individual choice to choose the outcome, overcome the ‘speed bumps’ and succeed! “One man’s Failure, is other man’s opportunity to succeed by not coping the other mans mistakes, but correcting them” Quote; Gene Landrum PhD. Quantum Theory of Everything!! Read it, do it, and succeed beyond your wildest dreams because you will be ‘doing’ your wildest dream(s)!! Because, of Quantum Teachings!! Additional Step is Believe in a Power greater than man, God if you will but there is only One God, with many names, spelled differently, but the Same, Same!

Gene Landrum, Author, PhD. Quantum Theory (h.d.)

I appreciate your R&D for the tiny home in cold climates. I’m looking forward to your finished product. My future project will be in a cold climate so I’m cheering you on and I personally do not have a problem with paying for quality that adds value over the long-term. Keep us posted on your progress.

Thank you so much for posting the information regarding the HRV units that work for tiny houses. I checked them both out and decided to go with the Lunos. I should have it in about 6 weeks. I am based out of Montreal, so I was able to go to the distributor and chat with them.

Thank you again,

Natalie

I googled them and found this post to be most helpful.

https://www.google.com/search?q=vacuum+insulated+panels&hl=en&tbo=d&source=lnms&tbm=isch&sa=X&ei=GQMWUfSvBYL0igKG0IGIDA&sqi=2&ved=0CAcQ_AUoAA&biw=1024&bih=677

Very excited to hear about this as I have lived in AK and traveled in the Yukon in nothing but a 12 year old van. Wish I had that very thing a few times, let me tell you.

Keep up the good work…will keep you in my favs.

Sorry, I didn’t know that link was going to run off the page. If you can’t corral it in, just google

vacuum insulated panels and you will find it easier.

This post and your website share nothing. There are too few details to tell if it even interests me. How many square feet is the building? How is electric done? How is it laid out? Is there a loft for sleeping or is that on the lower floor? Can it be built as a freestanding structure? How is plumbing done, if there is any. Etc. Your site really needs more information.

I’m not giving away all my secrets yet! Keep posted to the website for full details on the tiny house when testing is complete. Plans will also be available then. Cheers!

What would really be awesome is an insulation product that made a VIP sandwich. That way you could protect if from those pokey nails. 1.2″ of polystyrene on each side, VIP in the middle, and the whole thing would still be 3″ thick. I imagine the R value would be around 40-50? Even better would be a SIP with a VIP in the middle! hahaha. I keep coming back to this idea. Intriguing Keep us posted!